“SMALL INVESTMENT BIG RESULTS”

INFINITY ENGINEERING SOLUTIONS (IES)

Motivated by passion for innovation in surface treatment plants. We always put our innovation into action to achieve even higher level of quality and standards in every aspect of our work from planning, designing and manufacturing to erection, commissioning and service.

Build Your Dream

2+ Years Of Undefeated Success

IES is a full cycle provider from raw materials to finished products in the metals industries. Our professional life is dedicated to understanding and satisfying the customer’s needs through our experience, continuous team-up and flexibility.

10+

Successfully Project Finished.

2+

Years of experience with proud

25+

Hardwork Employee's

20+

Unique Products

Infinity Engineering Solutions

OUR RANGE PRODUCTS

Process Tanks

SS Tank

Bus bar Tank

PP Tank

Modular Tank

WHAT INFINITY ENGINEERING SOLUTIONS DO

“SMALL INVESTMENT BIG RESULTS”, with this slogan, we wish to support our customer in reaching their goals of environmental sustainability, work safety and improved final product quality, through technological innovation and a quick return on investment.

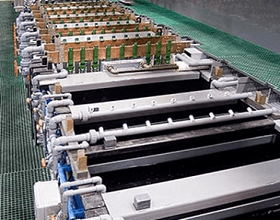

We Manufacture VAT, BARREL and BASKET Type Plating Plant in Turnkey Basis under one roof.

- Fully Automated Acid Zinc / Alkaline Zinc / Zinc Nickel / Zinc Iron plating line.

- Fully Automated Nickel & Chrome Plating line.

- Fully Automated Chrome Plating line.

- Fully Automated Anodizing line.

- Fully Automated Stripping line.

- Manual / Semi Automated Plating line.

Automation

Programming

Automated plating reduces the possibility of human error and fatigue for better productivity. More reliable deposits and plating to exact dimensions and thicknesses.

Automated systems are able to work around the clock, with faster deposition rates over tank plating and more accuracy meaning less post-plating machining is required.

Our own team work together Mechanical, Electrical and Programing in PLC. We work based on our customer requirements. We concentrate on output loads in tons and cycle time of plant.

Automation

SCADA

We supply and design SCADA system, You can Monitor your plating data Like Temperature, Timings, Plating time, Current, pH level, Dosing details all the parameters Monitor and store data.

As well monitor Transporter live locations, sensor failure, You can Analyze your report at any time. Send report through E-Mail, Monitor the process on remote location.

SUPPORT

Maintenance

Maintenance of machines with Automated plating line requires special skills. Manufacturers are the best people to support in maintaining these plants as total technology is available with them.

In order to help our customers in getting the best throughput from the machine, we have introduced the concept of Annual Maintenance Contracts (AMC) for the plants.

SUPPORT

SPARE PARTS

Your equipment has been engineered to meet your specifications. we can deliver the right spare part that fits your equipment and makes it available on site before an emergency happens.

Plating plant Accessories like Filters, Electrical Heaters , Transport Wagon Wheels, Belts, Rollers, Mechanical Plumber blocks etc., V Blocks and its Rubber pad, Rectifiers, Flight bars, Barrels, Tanks, Exhaust fan, Air Blowers, etc.,

OUR SATISFIED CUSTOMERS

Request a Quote

Ready to Work Together?